Fiberwood is a technology startup located in Järvenpää, within the Helsinki Ring of Industry area. The company develops fossil-free insulation and packaging protection materials for the construction industry, utilizing by-products from the forest industry and other natural fibers. The development of material innovations will take a leap forward in the fall of 2025, when the new pilot line is put into operation.

Recyclable materials from Side Streams

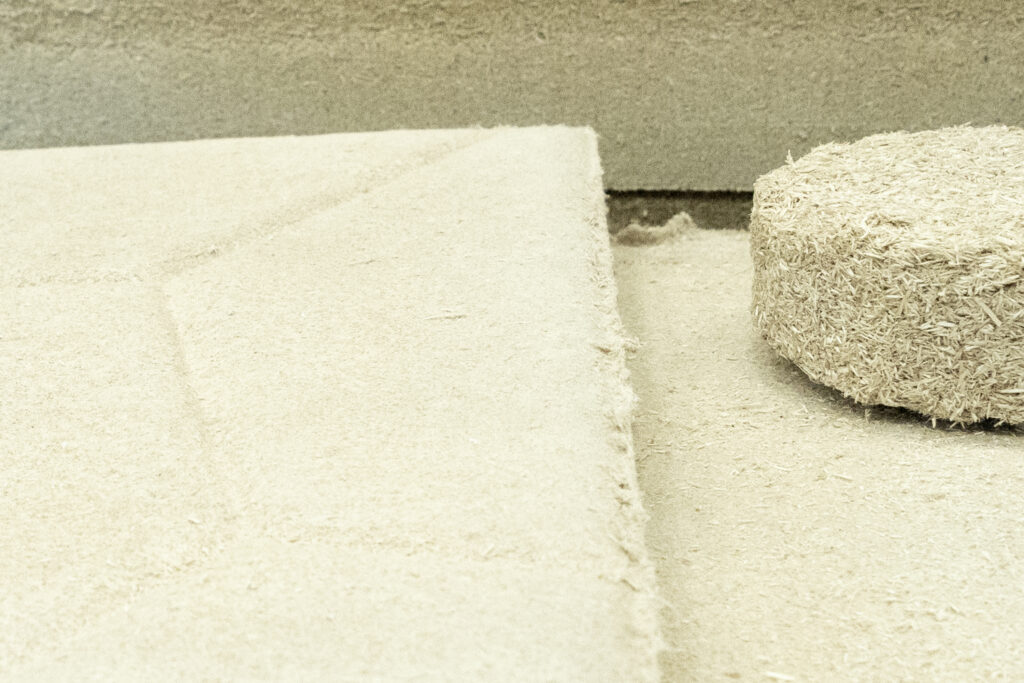

Fiberwood’s products are made from renewable natural fibers, primarily by-products of the mechanical forest industry. These side streams, which would otherwise be burned for energy, are transformed into fully recyclable and microplastic-free insulation and protective packaging materials.

“We are committed to sustainability in every part of our process. Our production technology uses a low-energy foam forming method and bio-based binders like starch, eliminating the need for plastic adhesives,” says CEO Tage Johansson. “The result is a recyclable material that lowers the environmental footprint wherever it’s used.”

A Strategic Location for Growth

Fiberwood’s operations are based in Järvenpää, an ideal location for industrial development within the Helsinki Ring of Industry. The area offers excellent logistics – including close access to Helsinki-Vantaa Airport – a skilled workforce, and a supportive network of partner companies. These factors are essential to Fiberwood as it scales production and strengthens its position in international markets.

“We chose this location not only for its logistical advantages but also for the vibrant ecosystem it offers. Our development centre will remain in Järvenpää as we expand globally,” says Karita Kinnunen-Raudaskoski, Head of Technology and Research.

Scaling Material Innovation Through Piloting

In 2022, Fiberwood established its first research facility in Järvenpää and moved to larger premises in 2024 to support rapid development. The company now employs 16 professionals, along with several external specialists working nearly full-time. The new demonstration and pilot plant marks the next step toward commercial-scale production and enables the company to test new applications and raw materials – including straw, oats, hemp, and beach grass.

“Our other teams are located in Hämeenlinna and Jyväskylä, so the Järvenpää area also makes sense from a national logistics perspective,” adds Kinnunen-Raudaskoski.

Finland – A Hub for Bio-Based Material Innovation

Finland plays a key role as a global leader in bio-based material development. Today, around twenty growth-stage projects in the country focus on the reuse of wood fiber, utilizing a range of raw materials and processing technologies.

“Our main competition still comes from fossil-based products,” says Kinnunen-Raudaskoski. “But we see other natural fiber-based innovators as collaborators rather than competitors. Together, we’re building a sustainable future and increasing the export value of Finland’s forest industry.”

Fiberwood

Fiberwood is a materials technology start-up developing fossil-free insulation and packaging materials for the construction industry from forest industry by-products and other natural fibres.

Text: Katja Humalainen

Photos: Katja Humalainen